When checking belts in the engine compartment make sure they – When checking belts in the engine compartment, make sure they are in good condition to prevent unexpected breakdowns. Regular inspections can identify potential issues early on, ensuring the smooth operation of your vehicle. This guide will provide a comprehensive overview of the types of belts, inspection procedures, common problems, and safety precautions related to engine compartment belts.

Understanding the significance of belt inspections and the potential consequences of neglecting them is crucial for maintaining vehicle safety and reliability.

Belts in the Engine Compartment: Importance of Inspections

Regular inspections of belts in the engine compartment are crucial for ensuring optimal engine performance and preventing costly repairs. Neglecting belt inspections can lead to premature wear, breakage, and catastrophic engine failure.

Types of Belts in the Engine Compartment: When Checking Belts In The Engine Compartment Make Sure They

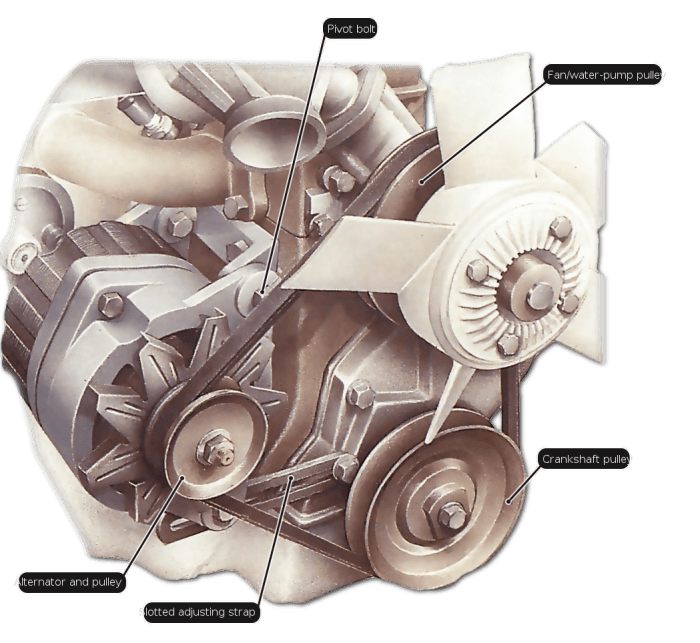

The engine compartment typically houses several types of belts, each with specific functions:

- Serpentine belt:Drives multiple accessories, such as the alternator, power steering pump, and air conditioning compressor.

- Timing belt:Synchronizes the crankshaft and camshaft, ensuring proper valve timing.

- V-belts:Similar to serpentine belts, but have a V-shaped cross-section and are used for older vehicles or specific applications.

Inspection Procedure for Engine Compartment Belts

Inspecting engine compartment belts involves a thorough examination for signs of wear and damage:

- Visual inspection:Look for cracks, fraying, or glazing on the belt surface.

- Tension check:Use a belt tension gauge or deflection method to ensure proper tension.

- Listening for noise:Unusual squealing or chirping sounds may indicate belt slippage or misalignment.

Common Belt Problems and Solutions

Common belt problems include:

- Belt wear:Regular use and exposure to heat and friction can cause belts to wear and deteriorate.

- Belt slippage:Worn or loose belts can slip, causing loss of power and reduced efficiency.

- Belt breakage:Severe wear, improper tension, or external damage can lead to belt breakage, resulting in catastrophic engine failure.

Troubleshooting and resolving belt issues involve:

- Replacing worn belts:Replace belts that show signs of excessive wear or damage.

- Adjusting belt tension:Adjust belt tension according to manufacturer specifications using a belt tensioner or deflection method.

- Inspecting pulleys and tensioners:Ensure that pulleys and tensioners are in good condition and properly aligned.

Safety Precautions for Belt Inspections

When inspecting belts in the engine compartment, safety precautions must be followed:

- Park safely:Park the vehicle on a level surface and engage the parking brake.

- Allow engine to cool:Wait until the engine has cooled down to prevent burns.

- Wear protective gear:Wear safety glasses and gloves to protect from debris or sharp edges.

- Keep hands away from moving parts:Avoid touching belts or pulleys while the engine is running.

FAQ Overview

What are the common types of belts found in the engine compartment?

Serpentine belts, timing belts, and V-belts are the most common types of belts used in engine compartments.

How often should I inspect my engine compartment belts?

Regular inspections are recommended every 6 months or 6,000 miles, or more frequently if you drive in harsh conditions.

What are the signs of a worn or damaged belt?

Cracks, fraying, glazing, and excessive wear are all indicators of belt damage.